Product introduction

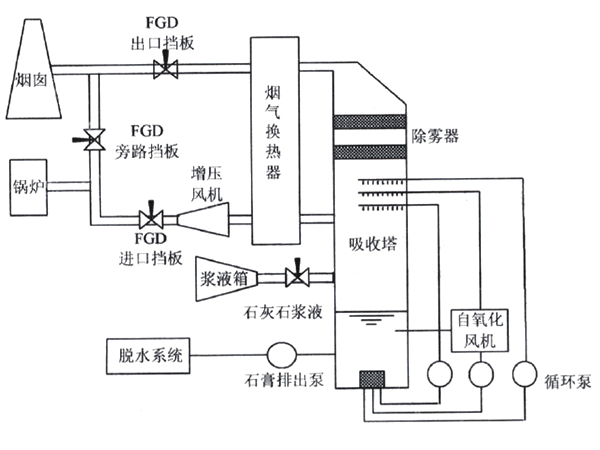

The limestone desulfurization (FGD) wet process technology is mature and has a high utilization rate in the desulfurization system; The inlet flue gas temperature of wet flue gas desulfurization is 80-90 ℃, and the outlet flue gas temperature is generally 50-60 ℃. The boiler flue gas temperature is generally 120-140 ℃, and some power plants use flue gas heat exchangers (GGH) to reduce the inlet flue gas temperature of the desulfurization system.

The integral heat pipe heat exchange system with low temperature dew point corrosion resistance can be used for flue gas desulfurization GGH or for flue gas re cooling systems, reducing the flue gas temperature to 80 ℃~90 ℃, improving desulfurization efficiency, and reducing energy and water consumption.

GGH schematic diagram